1. Nanoparticles produced by pulsed laser

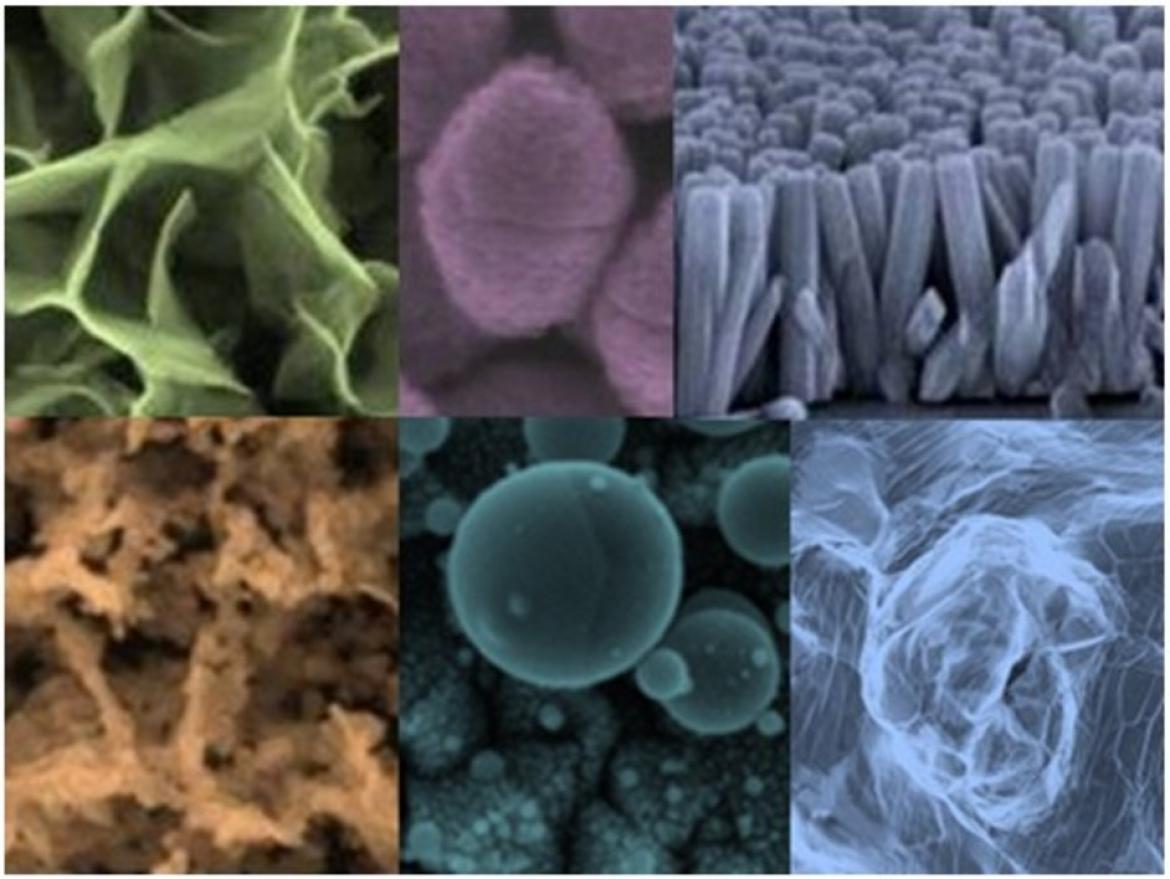

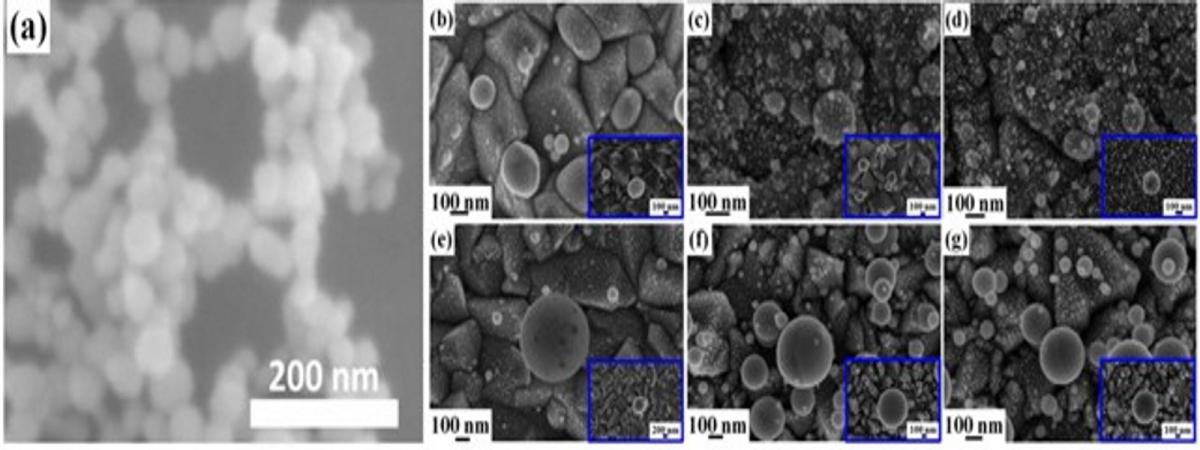

In this activity we will develop Pulsed Laser Ablation in Liquid (PLAL) methodologies to produce metal (Au, Ag (Fig. 1(a))) and metal oxides (TiOx) nanoparticles (NPs) [1]. Their photocatalytic and antibacterial properties will be tested. In addition, we, recently, observed that, by irradiating a Ti foil with a high power pulsed laser in water a black titanium oxide is formed. So, we will use the PLAL method to reach a fine control on the production of the black TiO2. Laser-based approaches will be developed to produce, also, Pd and Pt NPs on transparent conductive oxides since they are promising for catalysis, photocatalysis, and energy storage applications. So, Pd and Pt NPs will be produced on FTO (Fig. 1(b)-(g)) by laser annealing of deposited films [2]. The optical properties of the NPs will be analyzed. (Reference person: Francesco Ruffino)

[1] G. Cacciato, et al., “Green Nanotechnology-Overview and further prospects” p.110, InTech, (2016).

[2] F. Ruffino, et al., Physica E 83, 215 (2016).

Fig. 1- (a) Microscopy of laser ablated Ag NPs. (b)-(g) Microscopy images of Pt NPs formed on FTO surface after laser irradiations of deposited films.

2. Low-cost transition metal oxides nanostructures

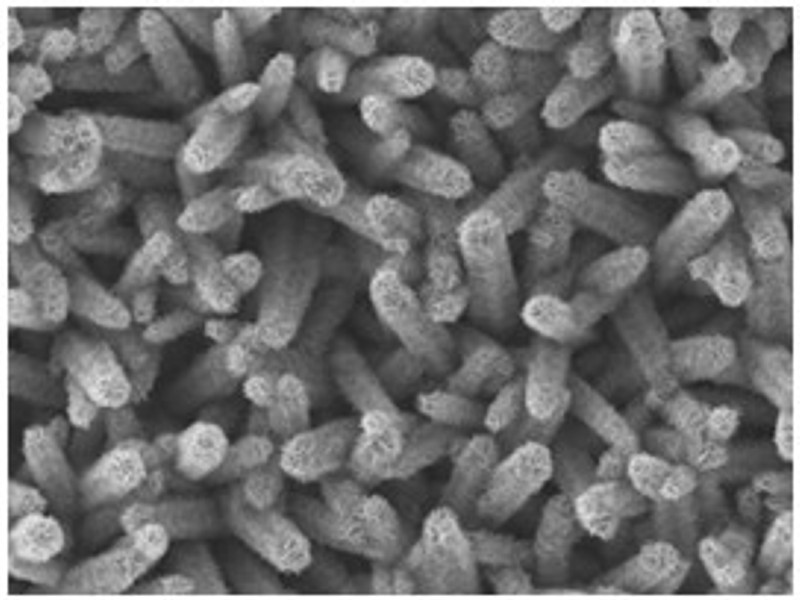

Our main goal is developing low-cost synthesis methods to get high control of metal oxides nanostructures in a large variety of shapes for multipurpose application. Low-cost fabrication is based on chemical (hydrothermal or chemical bath deposition, or sol-gel) and electrochemical techniques. Examples of well controlled synthesized nanostructures are ZnO nanorods [1], nanowalls [2], nanoflower and nanoeggs, as well as NiO nanowalls [3], nanofoam and nanoflakes. The added values of low-cost methods and materials’ biocompatibility and abundance are extremely appealing for large scale fabrication of functional nanostructures. Fabrication skill are joined with extensive morphological, structural, electrical and optical analyses, aiming at recipe optimization, materials durability, flexible substrate compatibility. Hierarchical structure are obtained by combining different growth techniques. (Reference person: Salvo Mirabella)

[1] V. Strano et al. J. Phys. Chem. C 2014, 118, 28189−28195

[2] K. Iwu et al. Cryst. Growth Des. 2015, 15, 4206−4212

[3] K. Iwu et al. Sensors and Actuators B 224 (2016) 764–771

Fig.2 Hierarchical ZnO-Ni nanorods/nanoflakes obtained through low-cost methods (chemical bath deposition followed by electrochemical pulsed deposition).

3. 3D graphene-based structures

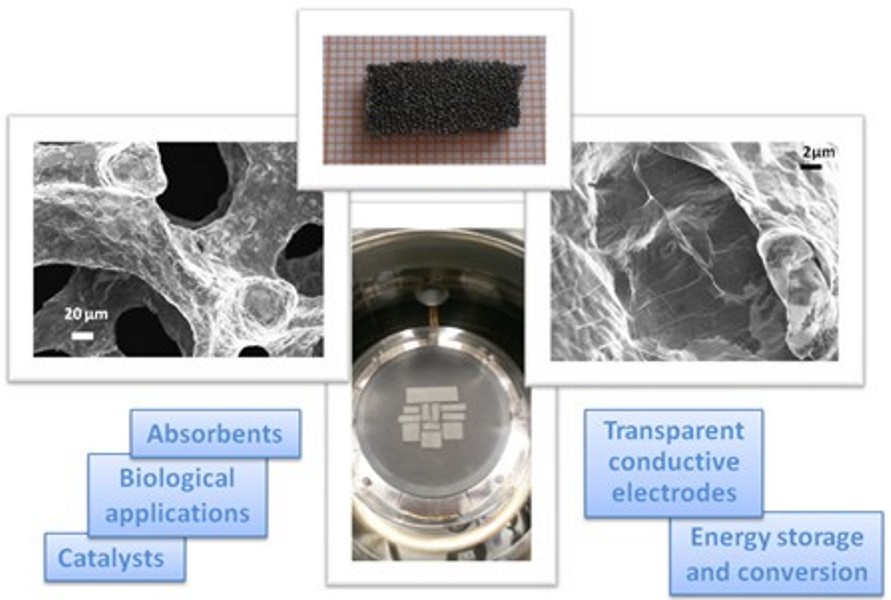

The research activity is focused on the realization of C-based materials by a dedicated Thermal and Plasma Enhanced Chemical Vapor Deposition. In particular, we deal with the synthesis and characterization of 3D structures (e.g. graphene foams, GFs) by using substrates of different nature and morphology as templates. Indeed, these 3D structures provide graphene-based materials with high specific surface areas (~850m2/g), strong mechanical strengths and fast mass and electron transport kinetics. All these properties make them interesting for applications in many fields where the available surface area plays a central role. We will try also to realize and characterize hybrid structures with other nanostructered materials (e.g. metals or oxides) that can open further promising ways of applications. (Reference person: Elena Bruno)

Fig. 3 two SEM images and a picture of a typical GF, together with an image of the CVD growth, with some possible application fields.