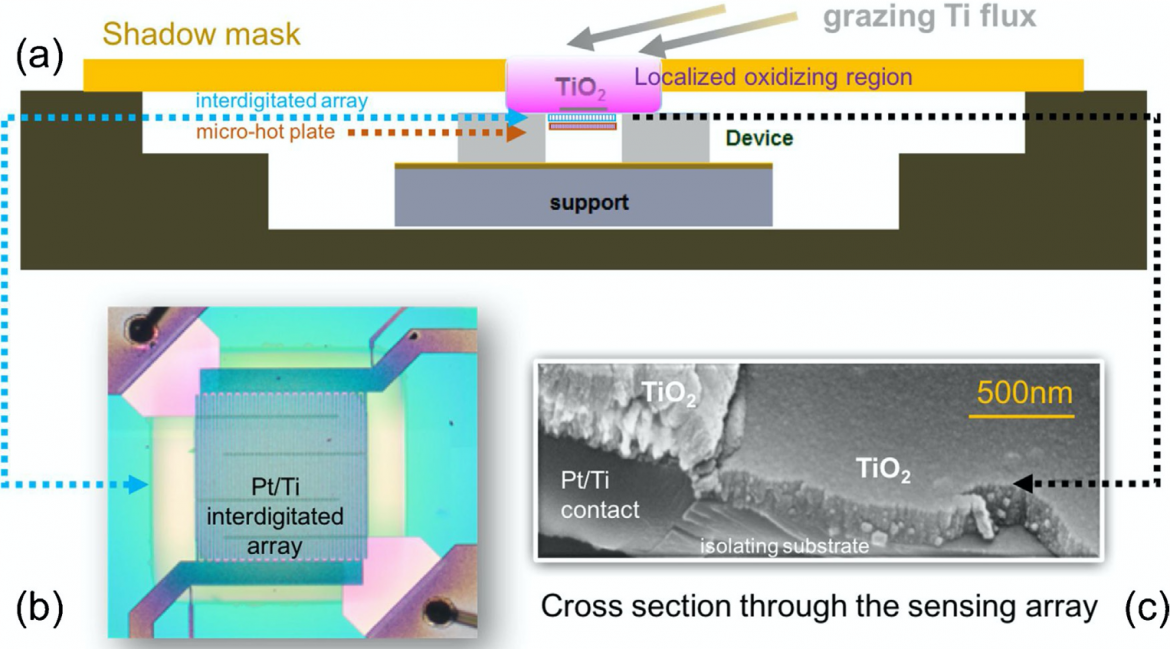

The Patent is based on the application of a newly-conceived TiO2 sponge deposited by sputtering with a customised equipment installed at the CNR-IMM laboratories.

The innovative method, called gig-lox, allows growing sponges with 45-50%Volume porosity and thickness from tens to thousands of nanometers.

US Patent 10,871,462

MOx-based gas sensor and manufacturing method thereof

AUTHORS:

Alessandra Alberti*, Lucio Renna**, Leonardo Gervasi**, Emanuele Smecca*, Salvatore Sanzaro*, Clelia Carmen Galati**, Antonello Santangelo**, Antonino La Magna*

*CNR-IMM zona industriale, 95121, Catania

** STMicroelectronics zona industriale Catania

Gas sensor, comprising: a substrate of semiconductor material; a first working electrode on the substrate; a second working electrode on the substrate, at a distance from the first working electrode; an interconnection layer extending in electrical contact with the first and the second working electrode, configured to change its conductivity when reacting with gas species to be detected. The interconnection layer is of titanium oxide, has a porosity between 40% and 60% in volume and is formed by a plurality of meso-pores having at least one dimension in the range 6-30 nm connected to nano-pores having at least one respective dimension in the range 1-5 nm